The world of electronics is evolving faster than ever, and businesses demand manufacturing solutions that are not only precise but also efficient. End-to-End PCB Assembly Services provide a streamlined approach, covering every aspect of the production cycle from the initial design stage to the finished, fully functional printed circuit board. By centralizing all processes under one roof, these services help reduce lead times, maintain consistency, and ensure top-tier quality for every project.

Comprehensive Manufacturing from Design to Delivery

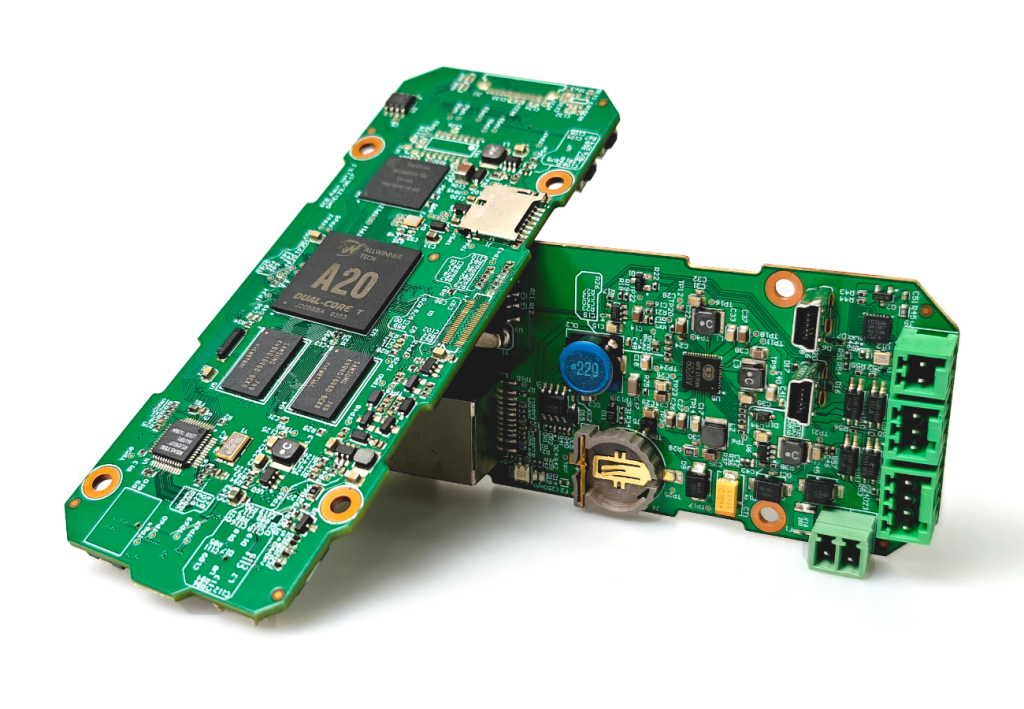

When working with electronics, every stage matters. From the moment an idea is translated into a schematic design, through prototyping, assembly, and quality testing, each step influences the final product’s performance. End-to-End PCB Assembly Services integrate these phases into one seamless workflow, eliminating the complexity of dealing with multiple vendors. This approach not only improves efficiency but also enhances communication between design engineers and production teams, ensuring that the finished boards meet exact specifications.

Why Complete Assembly Solutions Stand Out

Traditional manufacturing often requires businesses to handle different stages with separate suppliers, leading to delays and inconsistencies. In contrast, End-to-End PCB Assembly Services provide a unified process. By controlling design verification, component sourcing, surface mount technology (SMT) assembly, through-hole soldering, and testing within the same facility, manufacturers can ensure consistent results while reducing errors. The result is a product that meets deadlines without compromising quality.

Quality and Precision at Every Step

Precision is critical in electronics manufacturing. A minor defect can lead to significant performance issues or product failure. With End-to-End PCB Assembly Services, every stage is carefully monitored using advanced equipment and industry best practices. Automated optical inspection, X-ray analysis, and functional testing help detect issues before products are shipped. This rigorous quality assurance ensures that every board functions flawlessly, even in demanding environments.

Streamlined Component Procurement and Management

Component sourcing can be one of the most challenging aspects of PCB production. Shortages, counterfeit parts, and delivery delays can derail even the most well-planned project. One of the advantages of End-to-End PCB Assembly Services is that suppliers often have established relationships with trusted component distributors. This not only ensures timely delivery but also helps in sourcing authentic, high-quality parts at competitive prices, reducing the risk of supply chain disruptions.

Faster Turnaround with a Single Partner

Time-to-market is critical in today’s competitive industries. The integrated nature of End-to-End PCB Assembly Services significantly reduces production timelines. Since there’s no need to ship boards between multiple service providers, the assembly process moves forward without unnecessary delays. This advantage is especially important for industries like telecommunications, automotive, aerospace, and consumer electronics, where speed and reliability go hand in hand.

Cost Efficiency without Sacrificing Quality

While some may assume that using a single service provider for the entire PCB assembly process could be more expensive, the opposite is often true. End-to-End PCB Assembly Services cut down on logistics costs, reduce waste from rework, and streamline project management, all of which contribute to better cost control. This efficiency allows businesses to allocate more resources toward innovation rather than operational overhead.

Supporting Complex and High-Volume Production

Whether producing small batches for prototypes or scaling up to mass production, End-to-End PCB Assembly Services can adapt to the project’s demands. The same integrated process that benefits prototype development also applies to large-scale manufacturing, offering flexibility without compromising speed or quality. With advanced production lines and experienced technicians, these services are capable of handling complex multilayer boards, fine-pitch components, and intricate designs with ease.

The Future of Integrated PCB Manufacturing

As technology continues to advance, the demand for compact, high-performance electronics will only grow. Businesses seeking to stay ahead must rely on manufacturing solutions that combine expertise, advanced technology, and seamless operations. End-to-End PCB Assembly Services are at the forefront of this trend, providing the reliability, speed, and precision that modern industries require. By choosing a partner that offers complete manufacturing solutions in one place, companies can ensure their products meet the highest standards while reaching the market faster than ever before.