Next-Level Surface Refinement with Precision Technology

Edge Rounding Deburring Machines from Valgro India are transforming the way industries approach surface preparation and finishing. Built to deliver accuracy, reliability, and speed, these machines are ideal for applications requiring superior edge quality and burr-free results. By combining cutting-edge design with intelligent engineering, Valgro India’s systems offer a solution that simplifies and streamlines the deburring process across various sectors.

The Importance of Edge Rounding in Modern Manufacturing

With increasing demands for safety, assembly precision, and surface integrity, edge rounding has become a critical requirement in today’s production processes. Traditional methods often fall short in delivering consistency and control. Edge Rounding Deburring Machines solve this challenge by automating the task while maintaining uniform pressure and angle across complex contours. This ensures not only the removal of burrs but also the creation of smooth, rounded edges that improve product safety and enhance the bonding or coating performance of subsequent treatments.

Versatile Applications Across Industrial Segments

The flexibility of Edge Rounding Deburring Machines makes them highly suitable for a range of materials, including stainless steel, aluminum, copper, and mild steel. These machines are widely used in industries such as aerospace, electronics, fabrication, and automotive. The ability to handle small parts, large panels, and varied edge geometries gives manufacturers the confidence to maintain consistent surface finishing regardless of part complexity. Whether it’s preparing sheet metal components or precision parts, these machines deliver results that meet the highest industry standards.

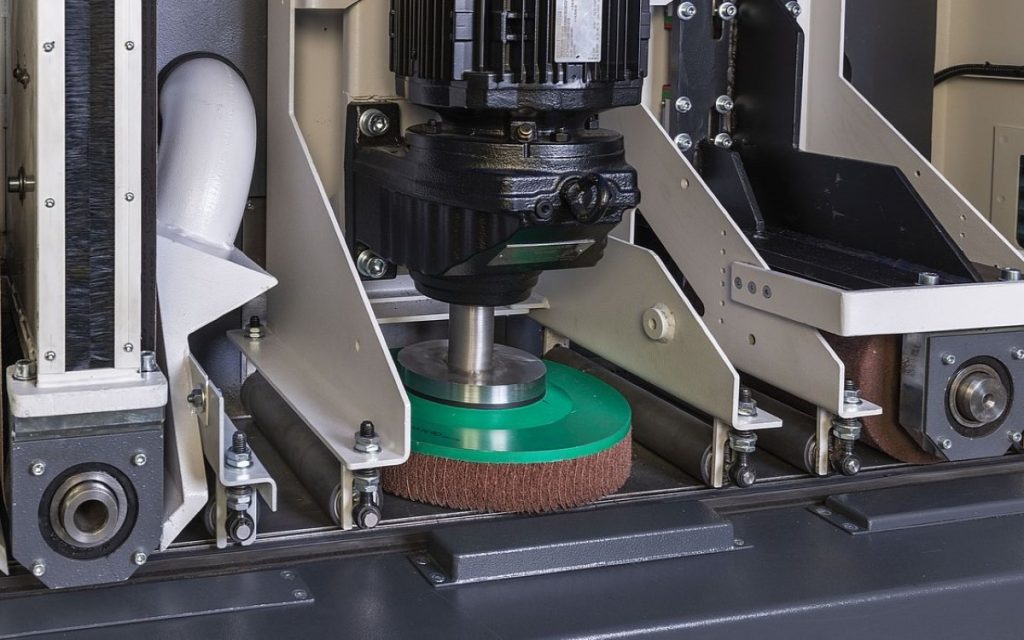

Advanced Engineering for Reliable Edge Processing

Valgro India’s Edge Rounding Deburring Machines are built with precision components and state-of-the-art automation. Their robust construction, variable speed control, and smart abrasive configurations allow users to tailor the process to exact specifications. The machines are engineered to ensure minimum material loss while delivering optimal surface results. With minimal operator intervention, they maintain repeatability and efficiency during long production cycles. This intelligent technology reduces downtime, increases productivity, and enhances operational control.

Enhancing Surface Quality and Product Safety

Sharp burrs and unprocessed edges can pose serious safety risks and impact component assembly. Edge Rounding Deburring Machines ensure that every part is finished to perfection, reducing the potential for cuts, injuries, or functional defects. The smooth and rounded edges also help in achieving better coating adhesion, minimizing peeling and flaking during painting, powder coating, or plating. This level of surface preparation is crucial for end-use durability and aesthetic consistency.

Sustainability and Waste Reduction in Finishing Processes

One of the standout benefits of using Edge Rounding Deburring Machines is the reduction in material waste and environmental impact. These machines eliminate the need for manual grinding or chemical-based deburring, both of which can be labor-intensive and environmentally harmful. By offering a dry and dust-controlled solution, Valgro India’s machines help industries maintain clean working conditions and sustainable production practices. This aligns with modern goals for cleaner, greener manufacturing without sacrificing quality or speed.

User-Centric Features and Intelligent Operation

Every model in Valgro India’s lineup of Edge Rounding Deburring Machines is designed with the operator in mind. Intuitive controls, safety interlocks, easy tool change systems, and minimal maintenance requirements ensure that the machines can be seamlessly integrated into any workflow. These features empower manufacturers to improve output quality while keeping operations smooth and cost-effective. With smart controls and digital monitoring options, users can track performance, detect anomalies, and maintain consistent output over time.

A Trusted Name in Surface Finishing Technology

Valgro India has earned its reputation as a leader in surface preparation and finishing solutions. Their Edge Rounding Deburring Machines represent the company’s commitment to innovation, quality, and customer satisfaction. By continually upgrading their machinery with modern features and tailored configurations, Valgro India ensures that clients across the globe receive dependable solutions built to outperform expectations. The brand’s dedication to excellence is reflected in every detail of the machines, from design to delivery.

Conclusion: A Smarter Way to Achieve Burr-Free Edges

For manufacturers seeking consistent performance, safety, and finish quality, Edge Rounding Deburring Machines from Valgro India present an intelligent investment. Engineered for diverse materials and demanding applications, these machines deliver the speed, accuracy, and versatility needed to stay competitive in a fast-paced production environment. By integrating this smart technology into their operations, industries can not only enhance product quality but also optimize costs and improve sustainability—making Valgro India the ideal partner for next-generation surface solutions.